Product Design for Manufacture and Assembly Boothroyd Pdf

In addition to the expected updating of data in all chapters this third edition has been revised to provide a top-notch textbook for university-level courses in product design and manufacturing. Provide a top-notch textbook for university-level courses in product Product Design for Manufacture and Assembly - Geoffrey Boothroyd - 2010-12-08 Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels.

Pdf Design For Manufacturing And Assembly Review Naol D E S S A L E G N Dejene Academia Edu

Since 1980 analysis techniques have been made available which can guide designers towards products which are easy to manufacture and assemble.

. To clarify this is the solutions manual not the textbook. Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels. In addition to the expected updating of data in all chapters this third edition has been revised to provide a top-notch textbook for.

In addition to the. Obtain design details Engineering drawings or Exploded 3-D views or Existing product or Prototype STEP 2. Professor Geoffrey Boothroyd gained a BSc in 1957 a PhD in 1962 for research into the temperature generated in metal.

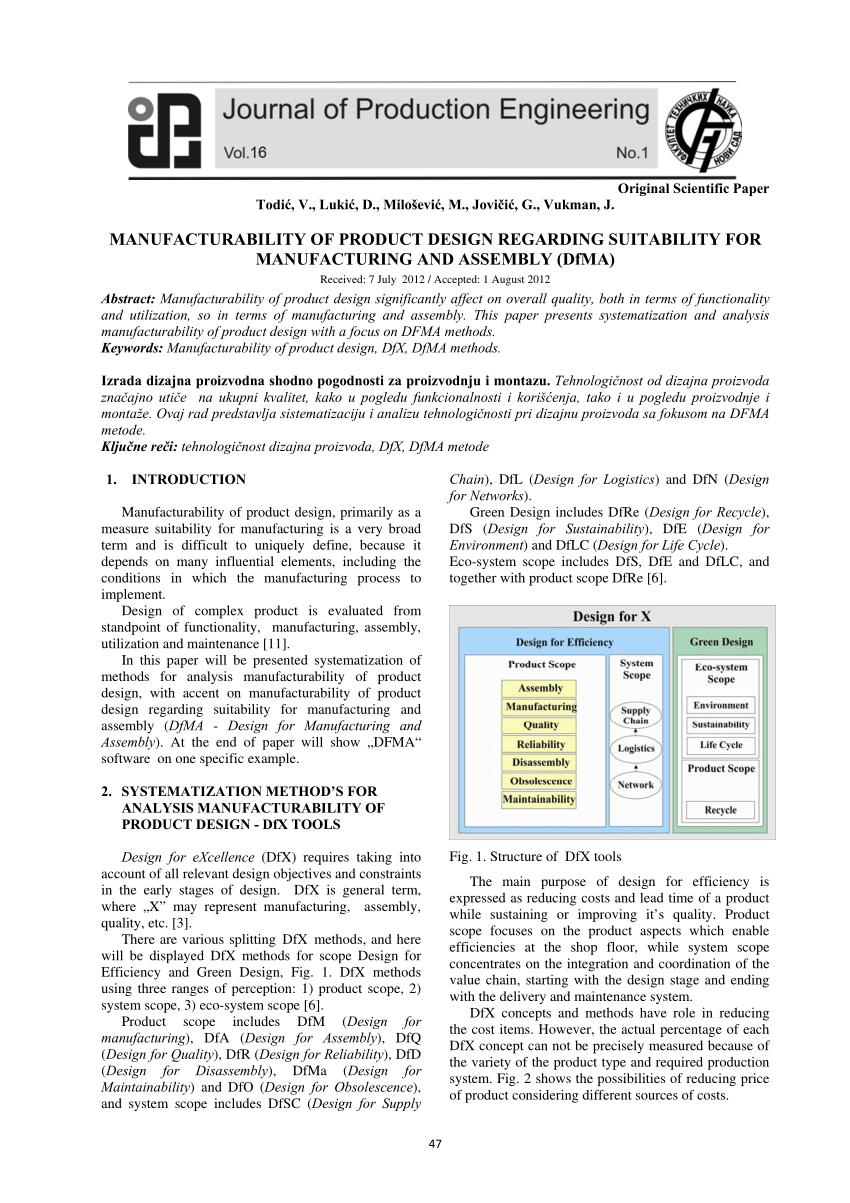

Knight Boca Raton London New York CRC Press is an imprint of the Taylor Francis Group an informa business. The technique was developed by Professors Geoffrey Boothroyd and Peter Dewhurst from work initially carried-out. A primary strategy in DFM involves minimizing the number of parts in a product.

Geoffrey Boothroyd Peter Dewhurst Winston A. Solutions manuals come in PDF format. SOLUTIONS MANUAL FOR PRODUCT DESIGN FOR MANUFACTURE AND ASSEMBLY 3RD EDITION BY BOOTHROYD.

Design for Manufacture and Assembly DFMA is now a widely accepted technique and is used in many manufacturing industries seeking to reduce development time lower manufacturing costs increase productivity and improve product quality. Suitable for use in product design and design for manufacture courses this book includes case studies of the application of design for manufacture and assembly DFMA techniques important industry changes and emphasis on trends such as design for power injection molding and surface mount devices. 7 2008-spring-2004 SKim 37 Workholding Immobilization of a workpiece for machining or assembly Jigs.

Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels. Locating and holding Provide maximum accuracy and ease of mounting Datum 2008-spring-2004 SKim B. Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels.

Complete solutions manual for product design for manufacture and assembly 3rd edition by boothroyd. Take assembly apart or imagine doing so -- assigning identification to each part as it is removed. DFM analysis needs to be done on all parts except the standard fasteners.

Grain Wood parallel grain Wood products Engineering polymers Porous ceramics Metal polymer composites Engineering alloys Engineering ceramics 0 100 200 300 Youngs modulus GPa 400 500 600 SOLUTIONS MANUAL FOR PRODUCT DESIGN FOR MANUFACTURE AND ASSEMBLY 3RD EDITION BOOTHROYD. Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for. ¾Design for Assembly DFA.

Up to 8 cash back Book Description. Product Design for Manufacture and Assembly Third Edition. Elastomers Foams Wood perp.

In addition to the expected updating of data in all chapters this third edition has been revised to provide a top-notch textbook for university-level courses in product. Design for DFx ¾Design for Manufacturing DFM refers to design activity that is based on minimizing the cost of production andor time to market for a product while maintaining an appropriate level of quality. Product design for manufacture and assembly.

The evaluation process is based on a typical framework of Design for ManufacturingDFM by Boothroyd Boothroyd et al 2001 that is taken into account in. Consider sub-assemblies as parts and analyse them separately recursively. Volume 26 Issue 7 July 1994 Pages 505-520.

In other words all chapters will be there. DFM stands for Design for Manufacture while DFA is for Design fo r. Containing more than 300 equations and the extensive data necessary to estimate manufacturing and assembly cost during product design benchmarking and should cost analysis this textbook gives students modern and effective tools for analyzing injection molding sheet metalworking die casting powder metal processing costs sand and investment casting and hot forging.

Product Design for Manufacture and Assembly Third Edition edited by Geoffrey Boothroyd Peter Dewhurst and Winston A. Author links open overlay panel Geoffrey Boothroyd 1. In addition to the expected updating of data in all chapters this third edition has been revised to provide a top-notch textbook for university-level courses in product design and manufacturing design.

Product design for manufacture and assembly Geoffrey Boothroyd Design is the first step in manufacturing and it is where most of the important decisions are made that affect the final cost of a product. Locating and holding workpiece guiding tools Fixtures. Hailed as a groundbreaking and important textbook upon its initial publication the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels.

Benhabib 38 3-2-1 rule of locating 6 dof D xD y z and R xR y z 3 support Points 1 2 and 3 eliminate R. Product Design for Manufacture and Assembly Third Edition Geoffrey Boothroyd Peter Dewhurst Winston A.

Pdf Manufacturability Of Product Design Regarding Suitability For Manufacturing And Assembly Dfma

Pdf Application Design For Manufacture And Assembly To Improving Product Design And Development Performance

Product Design For Manufacture And Assembly By Geoffrey Boothroyd

Pdf Design For Manufacturing Assembly Dfm Dfa Dfma Sheldon Pinto Academia Edu

No comments for "Product Design for Manufacture and Assembly Boothroyd Pdf"

Post a Comment